Unlaoding systems - automation solutions for postpress

Products

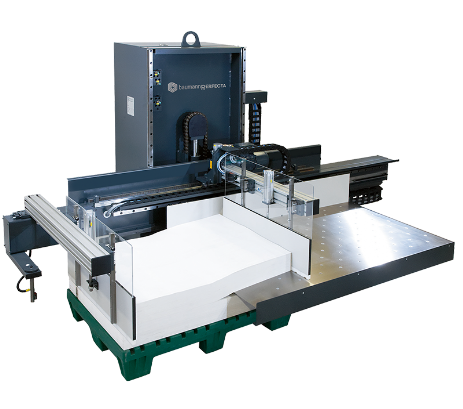

Unloading systems

The manual restacking of products after the cutting process requires a lot of time and effort. This process is automated by an unloader, with which single or multiple cuts can be highly precise restacked and thus offer high efficiency and economic viability. The different models offer solutions for the finishing process of piles up to 1800 mm height.

Unloader BA

The ergonomic and economically effective way to restack single and multiple cuts with high precision. The manual restacking of paper and cardboard after the cutting-process requires a lot of time and effort. The unloader gives you the opportunity to automate the restacking process. Unloaders BA N take up the material at the level of the table. The pile is positioned underneath the unloader table. The reams are restacked until a maximum pile height of 1100 mm has been reached. Unloaders BA N can either be installed on the right or on the left hand-side of the cutter. The design is very innovative (especially the principle of controlled axis), material and finish are of high-quality. The user friendly operator's panel with clear text display offers the oportunity to change all relevant parameters.

Advantages

- Increased productivity

- Very good restacking results

- Careful material handling

- Latest technology

Technical Data

| BA 3 | BA 5 | BA 7 | |||

| Sheet format max. [mm]* | 800 x 1200 | 920 x 1300 | 1250 x 1650 | ||

Pile height [mm] | 1400 / 1800 | 1400 / 1800 | 1400 / 1800 | ||

| Pile weight [kg] | 150 | 200 | 300 | ||

| Pallet height min. [mm] | 130 | 130 | 130 | ||

| * to be understood as max. pallet sizes | |||||

The values can vary depending on the equipment / additional options. Technical changes reserved.