Automatic cutting systems - automation solutions for postpress

Products > Cutting

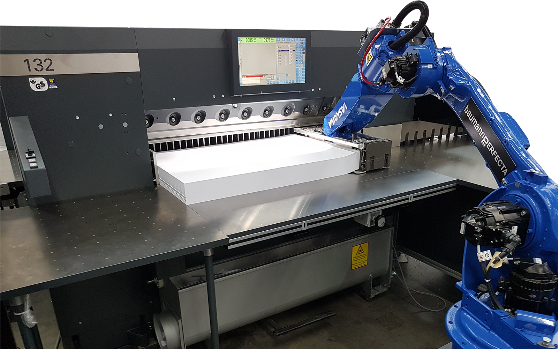

Automatic cutting system - BASS

For the cutting widths 115 | 132 | 168

The automation solution for the finishing process

The BASS system is the perfect automation solution for your finishing process - whether in label production, packaging printing or classic commercial printing. The combination of our high-performance high-speed cutters with modern industrial robots enables completely unmanned cutting to the finished cut end product. The specially developed gripper system "Multi-Paper-Tool" takes over the work of the operator. Whether gripping, rotating, aligning, tapping or transporting to other processes or machines - the robotic solutions can be configured so individually that they can practically transfer the operator's instincts to the robot. The BASS system can be operated on the baumannperfecta cutting machines of sizes 115 to 168. Of course, the high-speed cutters can also be operated manually at any time.

Quality Made in Germany

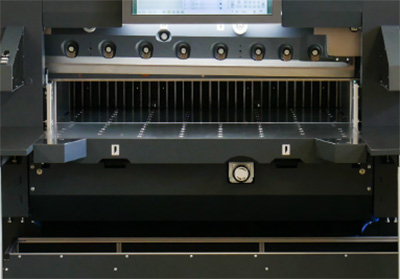

The BASS system was developed in Germany and is produced at our plant based in Solms. The latest generation of baumannperfecta high-speed cutters, in combination with the use of high-quality robotic components and the intelligent software of the control unit guarantee precision and high availability of the system. The robust basic construction of the machine frame ensures a smooth run and precise cutting results. The used parts and components are designed for continuous use, so that the cutters can be operated in 3 shifts - around the clock.

Perfect cutting results

Precision and performance characterize the baumannpferceta high-speed cutters. When cutting in automation, the robot not only takes over the tasks of the operator. Thanks to the intelligent control unit it also stands for sensitive touch, thus guaranteeing always perfect cutting results.

Easy to use

The control units of the cutters and the robots are designed for easy, intuitive operation via touch screen. Optionally, the cutting system can be equipped with an additional control panel, thus always offering a fast access to the parameter data.

High availability

The BASS system has been designed for 3-shift-operation. In combination with other peripheral machines as the BASA evolution or the vertical buffer, the complete jogging and cutting process can be fully automated. Moreover, the short set-up times guarantee high availability.

Efficiency

Besides the effect that you may use your staff more effectively thanks to automatic cutting, the BASS system has been optimized for the careful use of resources. State of the art drive technology and the use of energy-saving technologies stand for lowest possible consumption values.

Functional principle

Unmanned. Safe. Fast.

The heart of the cutting system is the integrated robot with the gripper system we developed specifically for paper processing, which takes over the operator's tasks during the cutting process. The robot can be configured in such a way that it can also take on the "instinct" of an experienced operator. Whether gripping, aligning, rotating, tapping or even passing on to an intermediate buffer or unloader. The work steps no longer require manual intervention. It can be fed to the right, left or alternately to the right and left.

An absolute highlight is offered by the robot technology in connection with the BASA evolution - the world's first and only fully automatic jogging and cutting system for further processing in the graphics industry. Simply load your pallet with the printed sheets into the BASA evolution and, at the end of the line, you will receive the ready-cut panels without further intervention by operating personnel - unloaded on another pallet.

The BASS system at one glance

Features

- High-speed cutter

- Industrial robot

- Automatic waste removal (ASE)

- Intermediate cut

- Alignment and forced guidance of the layers and single cuts

- Automatic and manual operation

- Easy operation via touch screen

- Process visualization with real image display

- Extendable thanks to modular design

- Automatic hand over of reams

Options

- Alignment pusher left/right-hand side

- Unloading left/right-hand side

- Side table with buffer function

- Alignment & feeding unit in ASE (automatic waste removal)

- Lowerable alignment stop

- Fully automatic 4-side-trim

- Fully automatic stack cutting

- Pusher for strips/cuts to be buffered

- Software Robotronic

- Additional, external touchscreen

- Automatic stacking of strips and cuts on air boards

- Feeding of two die cutters

- Pre-press data processing

- Feedback of production data (MIS)

- Remote service for remote maintenance

Optional extension and system solutions

- Loader and unloader (BB / BA)

- Transport and conveying systems

- Press-Station (BPS)

- Buffer systems (BVP / BMR)

- Automatic jogging machines (BSB)

- Fully automatic jogging machine (BASA)

- Air board system (BLL)

Technical Data

| BASS 115 | BASS 132 | BASS 168 | |

| Strip width [mm] | depending on the planned use | ||

Strip length [mm] | 300 - 1100 | 300 - 1300 | 300 - 1600 |

| Stack height [mm] | 130 | 130 | 130 |

| Cycle time [Sec.] | 25 | 25 | 25 |

The values can vary depending on the equipment / additional options. Technical changes reserved.